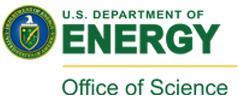

Arc Melt Furnace

- Instantly achieve temperatures greater than 3500°C (6332°F)

- Individual power supply to three separate electrodes for precise power delivery (>700 Amps combined power available)

- Gettered Argon atmosphere purity to ~1x10–15 ppm O2

- Expandable capabilities including single crystal growth and drop casting

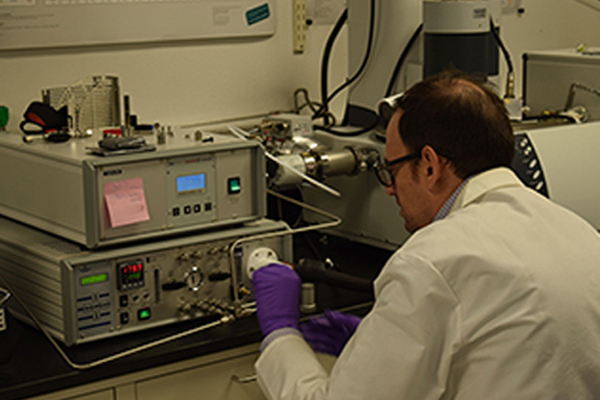

Housed in the EEML is a benchtop Centorr Vacuum Industries Tri-Arc Furnace with multiple hearth options all fitted with optional active water cooling. The furnace uses resistive heating delivered via common tungsten welding electrodes in a sealed and controlled atmosphere (usually O2 gettered Argon) to instantly or gradually achieve melt temperatures. This allows easy melting and synthesis of compounds containing conductive metals like molybdenum and aluminum, as well as hard-to-melt materials such as carbon. The EEML's arc melt furnace's main use over the last three years has been to synthesize uranium bearing compounds as they are studied for possible deployment in both conventional and advanced reactors.

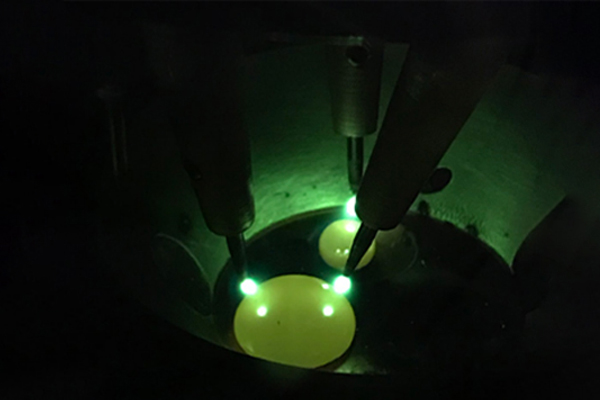

Glovebox

- Powerful gas purifier unit (DP as option for 24/7 purification)

- Dual station with customized power feed-throughs

- Equipped with a Ohaus analytical balance, polishing and grinding media and Carver press

- O2 and H2O levels maintained at < 1 part per million

- Closed loop circulation with nuclear filtered exhaust

- Negative or positive pressure operation

The EEML houses an Mbraun Uni-Lab Pro SB dual station glovebox for dU storage and handling with a fully automatic 1-filter column gas circulation system for cleaning inert gas and to absorb O2 and H2O. The system is operated with Ar at pO2 and pH2O < 0.1 ppm. The glovebox is used for both pyrophoric metal storage and air sensitive sample preparation.

Scanning Electron Microscope (SEM)

- Accelerating voltage range: 0.3 kV–20kV

- Magnification range 16x to 60 kX (SE) and 50 kX (BSE)

- Resolution: 5 nm

- Low vacuum range 6 to 100 Pa

- Secondary electron detector (high vacuum)

- Backscattered electron detector (high/low vacuum)

- Oxford Instruments energy dispersive x-ray spectroscopy

The lab utilizes an in-house Hitachi FlexSEM 1000 Scanning Electron Microscope with a backscatter detector and EDS for microstructural characterization. It has variable pressure capabilities and allows for navigation of specimens with motorized stage (3 axis tilt and rotation). It is equipped with an Oxford Instruments EDS detector and AztecOne data analysis software for elemental analysis. It provides information of sample topography, morphology, porosity, and phase segregation. Samples that have been characterized include ceramics, intermetallic compounds and alloys, particle fuel forms, and powders.

Simultaneous Thermal Analyzer

- Differential scanning calorimetry

- Thermogravimetric analysis

- Varied temperature range—RT to 1600°C

- Multiple atmospheres including inert (e.g. argon), oxidizing (e.g. oxygen, steam), reducing (e.g. hydrogen)

The lab utilizes a paired Netzsch Simultaneous Thermal Analyzer (STA) 449 Jupiter F3—Quadrupole Mass Spectrometer (QMS) Aeleos Quadro. The paired analytical instruments quantify thermogravimetric data (e.g. mass loss/gain) and gaseous products from samples under varied conditions as functions of time, temperature, and gas atmosphere. Multiple furnaces and fixturing options facilitate testing of fuels (e.g. U3Si2), inert homogeneous (e.g. silicon carbide) and non-homogeneous materials, environmental samples (e.g. soils), and varied applications.

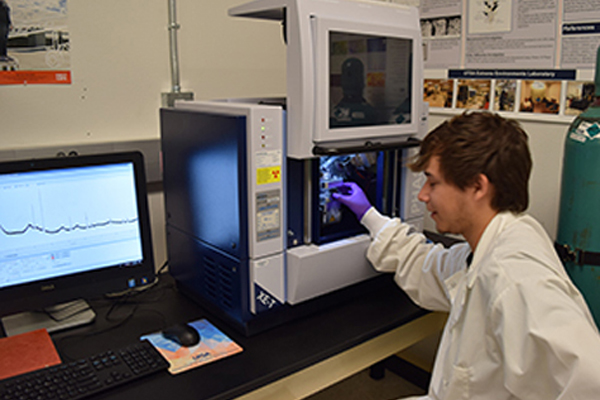

X-Ray Diffraction (XRD)

- Analyze crystallography of powder samples

- Used for phases characterization of as fabricated and post-experiment samples

- Lynxeye detector allows for high resolution data acquisition in relatively short scan times

- Low background and environmental sample holders allow for a range of sensitivity and precision

The lab's powder diffractometer is a Bruker D2 Phaser equipped with a LYNXEYE XE-T detector and copper anode. We have some optical slit variations on hand, including the ability to change the diffraction slit size (1mm, 0.06mm, 0.04mm) and the air scatter screen opening (4mm or 2mm). In addition, we use 4 degree soller slits. We mostly use a zero background wafer with a polymer dome sample holder to secure our rad powder samples which are a pretty serious inhalation hazard.